Yesterday the main span of the FIU-Sweetwater UniversityCity Bridge collapsed, with an unknown amount of fatalities:

The graceful pedestrian bridge was swung into place on Saturday. Heralded as a triumph of “accelerated construction,” the walkway would allow pedestrians to safely cross eight lanes of traffic separating the campus of Florida International University from the small city where many of the students lived.Five days later, around midday Thursday, the walkway collapsed in a pile of 950 tons of metal, concrete and dust, before ever opening to pedestrians. At least six people were killed, according to the Miami-Dade County police. Some reports put the number of dead a high as 10.

I wanted to quickly talk about what is going on here, since there are lots of idle speculation on the cause. Some disclaimers: I’m a trained, yet unregistered architect, and not an engineer. But I am trained in structures, and if you want to talk offline about shear forces on a simple beam, I’m all ears.

This accident ill no doubt be taught as a case study to architects and engineers, much like the Kansas City Hyatt Regency walkway collapse or the Kemper Arena Roof Collapse:

Here’s some basic facts about the bridge which I feel are material to this accident.:

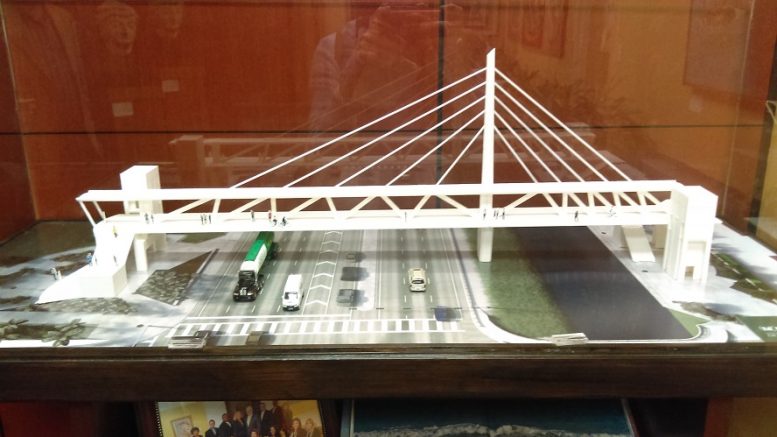

- The bridge was designed as an asymmetrical cable-stayed bridge

- The 174-foot, 950-ton section of the bridge was built adjacent to Southwest Eight Street

- The main span appears to be constructed of prefabricated concrete sections, the post-tensioned in place

- The span was then rotated and moved to be installed on two supports

- The cable-stay were not in place yet

- The bridge appears to not have shifted off the end supports (the two ends rotated along what looks like a pin connection).

- It appears that the span would act as a truss, or have truss-like forces on it

It appears that the bridge failed in tension on the bottom chord (where people would walk), due to either asymmetrical weight or punching shear from one of vertical truss webs. The failure point appears to be 1/3rd from end of the span – in a simply supported beam such as this span, the highest shear stress (think material deforming) is at the ends of the span, and the largest moment (or propensity to turn over or rotate) is at the center of the span. So failure at the 1/3rd point is cause for concern and is the asymmetrical nature of the truss. Moving the bridge and installing it shouldn’t have been an issue, and this type of span construction isn’t new. That being said, it isn’t exactly a common type yet.

Here are some questions I would want to know in order to determine how it failed:

- What were the condition of the concrete sections? Were they given adequate time to cure?

- What condition are the post-tensioning system? Was it done correctly?

- During movement, were any of the sections knocked out of alignment?

- Why does it appear that some of the vertical webs punched through the bottom chord?

- What was the schedule? Were the contractors behind or at schedule?

- What unforeseen loads were placed on the bridge?

What is highly probable is that a series of small changes, or construction, or fabrication mistakes reduced the overall factor of safety on the span, speeding failure.